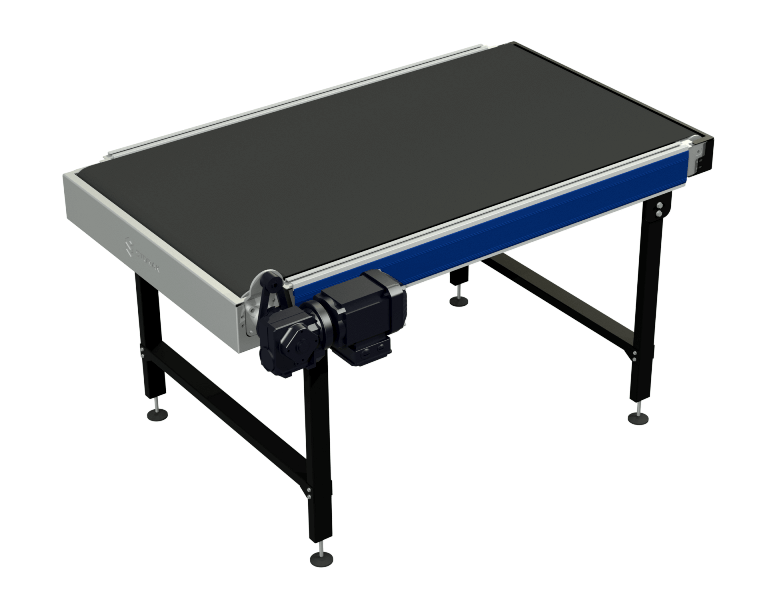

400V Conveyor Belt

The belt conveyor is used for the transport of unit loads that are not suitable for roller conveyor lines, and for all types of unit loads in case of inclines and declines. The drive medium is a center drive prepared for SEW motors. The belt material is PVC 2 layer black. PVC side cover caps both sides included. Delivered completely assembled, or as pre-assembled submodules if the conveyor is longer than 3 meters. The frame built up out of anodised extrusion aluminium profiles.

| General Data | |

|---|---|

| Conveyor speed | 0,1 to 2,0 m/s |

| Max. load capacity | 50 kg (Maximum load capacity is depending on the combination of speed & load) |

| Ambient temperature | 0° to 40°C |

| Ambient humidity | Less than or equal to 90% (no condensation) |

| Noise level | < 70 dB (Noise level can vary due to surrounding conditions) |

| Incline / Decline | 6° – 9° – 12° – 15° – 18 |

| Slider type | Plate and steering string |

| Frame | Aluminium extrusion profile |

Streamlining Material Handling with 400V Belt Conveyors

Material handling is a crucial aspect of various industries, from manufacturing and distribution to retail and hospitality. One technology that has revolutionized material handling is the 400V Belt Conveyor. In this article, we’ll explore the benefits of these conveyors and why they are an essential investment for businesses seeking optimized material handling.

Understanding 400V Belt Conveyors

400V Belt Conveyors are a type of powered conveyor system that uses a belt to transport materials or goods from one point to another. The belt is driven by a 400-volt motor, which provides the necessary power to move the belt and transport the items. This conveyor design is particularly useful for inclines and declines where the speed and orientation of the goods have to be controlled.

The Advantages of 400V Belt Conveyors

- High Efficiency:

One of the most significant benefits of 400V Belt Conveyors is their high efficiency. They can handle large volumes of materials or goods, making them ideal for businesses with high production rates. By automating material handling, businesses can increase their output and reduce the risk of errors or delays. - Versatility:

400V Belt Conveyors can handle a wide range of materials, from small packages and boxes to larger items. They are also suitable for different industries, including food processing, automotive, and pharmaceuticals. This versatility makes them a cost-effective solution for businesses seeking a flexible material handling system. - Improved Safety:

Manual material handling can be dangerous and can cause injuries to employees. However, 400V Belt Conveyors improve workplace safety by automating the material handling process. This reduces the risk of employee injury, thereby ensuring a safer work environment. - Space Optimization:

Another significant advantage of 400V Belt Conveyors is their space-saving design. These conveyors can be designed to fit into tight spaces, making them suitable for businesses with limited floor space. This space-saving feature is especially valuable in warehouses or manufacturing facilities where every square foot matters. - Low Maintenance:

Maintaining conveyor systems can be time-consuming and costly. However, 400V Belt Conveyors require minimal maintenance. With fewer moving parts and the absence of complex mechanical systems, these conveyors are reliable and have longer lifespans. This translates to reduced downtime and increased productivity for businesses.

In conclusion, 400V Belt Conveyors offer a winning combination of efficiency, versatility, safety, space optimization, and low maintenance. These conveyors are a smart investment for businesses seeking to streamline their material handling processes and enhance overall productivity.

Contact us for a quotation on your project.

Get A Quote Today

Talk to us about your project, we can assist you with advice and know-how from our decades of experience.